See our machines in action

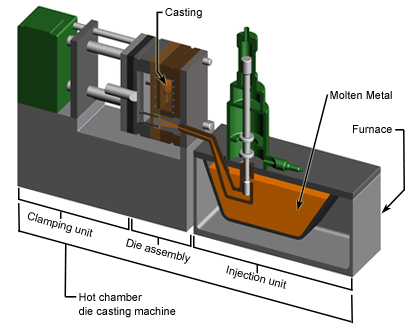

Our Die Casting Department

Peripheral Equipment

Robotic Arms

All 12 of our conventional machines are outfitted with Kawasaki robotic arms for load and unload.

Trim Presses

Each Conventional casting work cell has Trim Press